As catalyst is the heart of the reforming technology, Defiant Renewables has taken initiative and shown expertise in catalyst fabrication for reforming technology. The primary attention has been paid to the cost of the catalyst and performance as well. In order to reduce the cost of the catalyst, our efforts were given on non-noble metal based catalyst, low cost clay support and catalyst design. To achieve comparable performance to that of noble metals, perovskite, ABO3, type of catalysts have been chosen. However, single metal catalysts are also used. Promoters, oxide ion conducting materials and refractory materials are also added to the catalyst to improve the properties of the catalyst. As a part of catalyst design, principally two types of catalyst have been designed: nano-structured composite and layered-type catalyst.

As this structure requires extremely small space in the reactor, it opens up the opportunity for the design of micro-reactor. In future, we shall have plan for micro-reactor design.

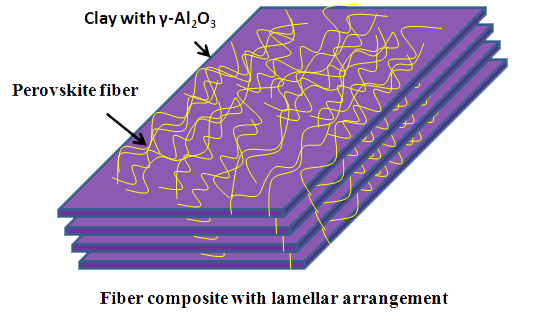

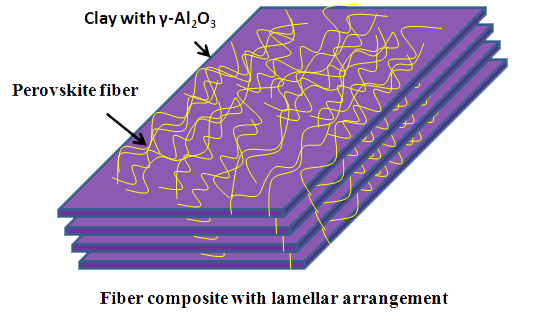

Layered type catalyst with fibrous active phase

The catalyst consists of several layers; each layer comprises clay support and fiber active phase. As the fiber fabrication involves agricultural waste like jute, clay, and non-noble metal, the cost of the catalyst becomes cheaper, thereby making it cost effective and competitive to other expensive catalysts available in the market.

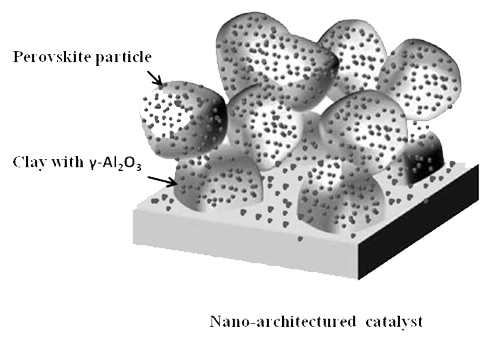

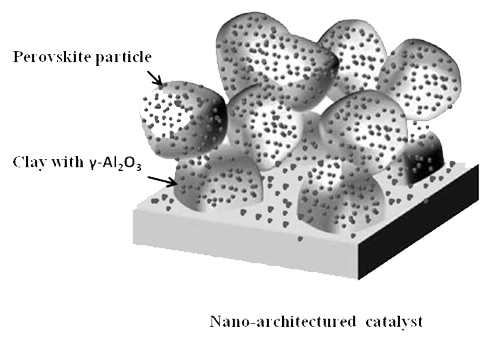

Nano-structured type catalyst with particulate active phase

The catalyst is basically nano-structured particulate composite which consists of clay support as matrix and active phase as particles dispersed in the matrix. As the particles synthesis involves agricultural waste like tamarind karnel powder (TKP) and carboxymethylcellulose clay (CMC), and non-noble metal, the cost of the catalyst becomes cheaper, thereby making it cost effective and competitive to other catalysts which are expensive.