Services.

Chemical Looping Reforming Technology

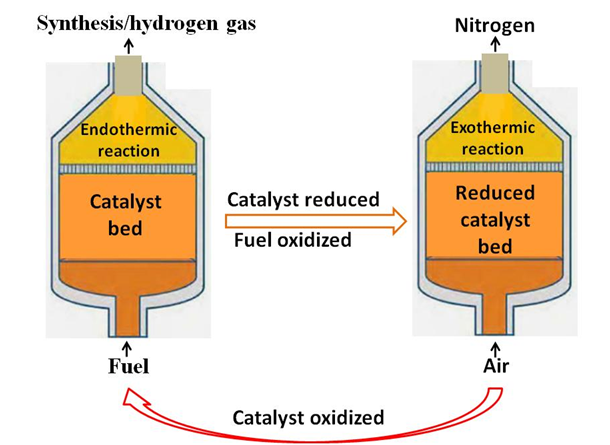

A chemical looping reforming is a process for the production of hydrogen and synthesis gases with no carbon dioxide emissions to the atmosphere. The process occurs in rotation: reduction of oxide catalyst by hydrogen, the reduced catalyst catalyzes reforming reaction with the introduction of fuel, oxidation of catalyst by air, reduction of catalyst and reforming reaction by fuel; oxidization of catalyst by air. The advantage of this process over other reforming process is the long term catalyst stability and generation of pure nitrogen during oxidation of catalyst by air. The absence of nitrogen in the product gases causes no dilution of product synthesis/hydrogen gases.

- Oxygen is provided to the fuel/hydrocarbons via catalyst which has the property to carry oxygen.

- Catalyst gets reduced by the fuel.

- The catalyst is subsequently oxidized with the flow of air and exothermic oxidation reaction occurs.

- The heat generated during exothermic reaction provides necessary heat for the following endothermic reforming reaction.

- Advantage of CLR over ATR is the higher hydrogen/synthesis gas yield.

- Works as stand-alone system.

- Provides power solution to remote and off-grid areas.

- Extremely new in India.